Dog leg repair is a specialized technique vital for maintaining efficiency and safety in electric and hybrid vehicles, ensuring seamless power transfer through the critical mechanical linkage connecting motor to transmission. Collision centers offer advanced solutions like paintless dent repair for minor damage, preserving structural integrity and optimizing vehicle performance. This complex repair involves skilled technicians addressing intricate wiring harnesses and powertrains, with modern advancements using high-strength materials, automated systems, and digital diagnostics. Future trends aim for eco-friendly solutions through 3D printing and recycling to minimize environmental impact.

In the realm of electric and hybrid vehicle repairs, dog leg repair stands out as a crucial component, ensuring efficient power distribution. This article delves into the intricate world of dog leg repair, exploring its basic concept, unique challenges, and modern approaches. From understanding the role of dog legs in e-vehicles to deciphering the complexities that set them apart from conventional cars, we provide insights into the future trends shaping this game-changer in automotive technology.

- Understanding Dog Leg Repair: The Basic Concept and Its Role in Electric/Hybrid Vehicles

- The Challenges and Complexities of Dog Leg Repair: What Makes It Unique in the Automotive Industry

- Modern Approaches to Dog Leg Repair: Techniques, Tools, and Future Trends for Electric and Hybrid Vehicles

Understanding Dog Leg Repair: The Basic Concept and Its Role in Electric/Hybrid Vehicles

Dog leg repair is a specialized technique essential for maintaining the efficiency and safety of electric and hybrid vehicles. This process involves addressing a unique component, the dog leg, which plays a critical role in powering these advanced vehicles. The dog leg, essentially a mechanical linkage, connects the motor to the transmission system, ensuring seamless power transfer. In the complex landscape of vehicle bodywork, where precision is key, dog leg repair demands expertise and specialized tools.

When damage occurs, whether from an accident or normal wear and tear, it’s crucial to address the issue promptly. Reputable collision centers often offer advanced solutions, including paintless dent repair for minor dents and scratches, without compromising structural integrity. This meticulous process not only restores the vehicle’s aesthetics but also guarantees optimal performance, ensuring the dog leg continues to facilitate the smooth operation of electric and hybrid powertrains.

The Challenges and Complexities of Dog Leg Repair: What Makes It Unique in the Automotive Industry

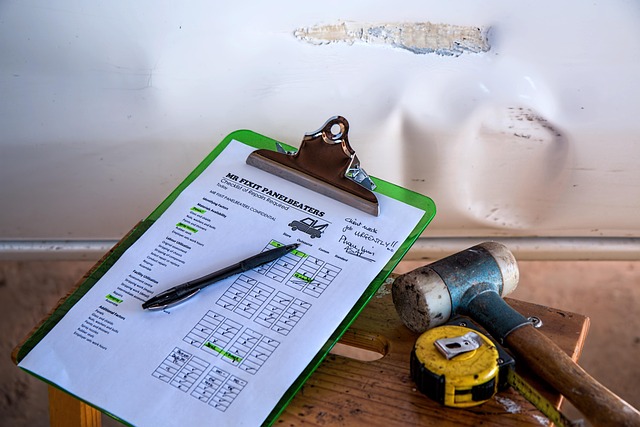

Dog leg repair presents a unique challenge within the automotive industry, particularly in electric and hybrid vehicles. Unlike conventional car repairs, these modern vehicles have intricate systems that require precise handling due to their complex electrical and mechanical integrations. A dog leg, a crucial component often found in vehicle suspension systems, plays a vital role in maintaining stability and control—its repair demands specialized knowledge and equipment.

In the realm of auto collision repair, bumper repair, and general collision repair centers, dog leg repair stands out due to its sensitivity. It’s not just about replacing a part but ensuring the alignment and functionality of the entire suspension network. The complexity increases with electric and hybrid vehicles, where intricate wiring harnesses and power trains must be carefully managed during the repair process. This makes dog leg repair both an art and a science in collision repair, requiring skilled technicians to navigate through intricate systems for successful restoration.

Modern Approaches to Dog Leg Repair: Techniques, Tools, and Future Trends for Electric and Hybrid Vehicles

Modern approaches to dog leg repair in electric and hybrid vehicles have evolved significantly over recent years, driven by advancements in technology and a growing demand for efficient, sustainable transportation. The unique challenges posed by these vehicles, such as their lightweight construction and complex drivetrains, necessitate specialized techniques and tools. One notable trend is the increased use of advanced materials, including high-strength steels and composite components, which offer superior durability and reduce the need for frequent repairs.

Automated systems and robotic technology are also playing a crucial role in streamlining dog leg repair processes. These innovations ensure precision and consistency, allowing body shop services to deliver high-quality tire services and car body repairs. Furthermore, the integration of digital diagnostic tools enables mechanics to identify issues more quickly and accurately, leading to faster turnaround times and improved customer satisfaction. Future trends suggest a greater emphasis on eco-friendly solutions, with developments in 3D printing and advanced recycling techniques aiming to minimize waste and reduce the environmental impact of vehicle repairs.

Dog leg repair is a specialized technique that plays a vital role in the automotive industry, particularly in electric and hybrid vehicle repairs. By understanding its basic concept, navigating the challenges, and embracing modern approaches, technicians can ensure these vehicles’ drivability and efficiency. As the demand for electric and hybrid cars continues to grow, staying informed about innovative dog leg repair methods will be crucial for maintaining and repairing these advanced vehicles effectively.