Dog leg repair, crucial in automotive restoration, addresses structural damage caused by accidents or wear and tear. Efficient scrap material management and innovative eco-friendly techniques, like using recycled materials and biodegradable composites, are vital for sustainable dog leg repairs. Forward-thinking auto repair shops have successfully implemented these practices, minimizing waste while maintaining vehicle integrity and contributing to a greener future.

In the realm of construction and infrastructure, dog leg repairs play a crucial role in enhancing road safety. However, traditional methods often overlook environmental considerations. This article explores the intersection of environmental sustainability and dog leg repair. We delve into eco-friendly approaches, examining sustainable materials and innovative practices that minimize ecological impact. Through real-world case studies, we demonstrate the effectiveness of these strategies, highlighting how responsible repairs can contribute to a greener future for our roads.

- Understanding Dog Leg Repair: The Environmental Impact

- Sustainable Materials and Practices for Dog Leg Repair

- Case Studies: Eco-Friendly Dog Leg Repair in Action

Understanding Dog Leg Repair: The Environmental Impact

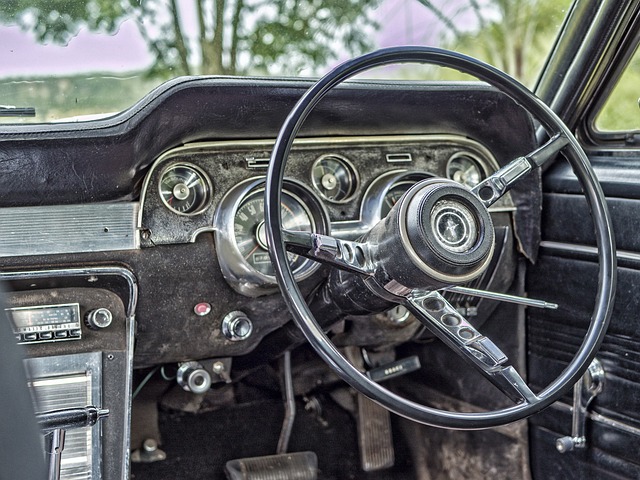

Dog leg repair is a critical aspect of automotive restoration, addressing structural damage often caused by accidents or wear and tear. This process involves replacing or reinforcing bent or broken components in a vehicle’s frame, particularly around the dog leg area—a crucial joint connecting major framework elements. The environmental impact of dog leg repair is significant, especially when considering the waste generated from removing damaged parts and the resources required for replacement.

In an auto collision repair center, efficient management of scrap materials is vital to minimize ecological effects. Auto maintenance professionals can contribute to sustainability by utilizing recycled components whenever possible and implementing proper disposal protocols for hazardous materials. Moreover, staying updated with innovative repair techniques and eco-friendly practices ensures that dog leg repairs not only enhance vehicle structural integrity but also align with the growing demand for sustainable auto collision repair solutions.

Sustainable Materials and Practices for Dog Leg Repair

In the realm of dog leg repair, adopting sustainable materials and practices is a growing trend, aligning with the broader environmental consciousness. Eco-friendly options for car damage repair extend beyond traditional aesthetics to encompass the very essence of ecological stewardship. For instance, utilizing recycled metal in car body restoration not only reduces the carbon footprint but also diverts valuable resources from landfills. Similarly, biodegradable composites and bio-oils can be employed as alternatives to conventional petroleum-based products during collision repair processes, minimizing environmental impact.

These sustainable materials and practices don’t compromise quality or durability; instead, they offer innovative solutions for dog leg repair, car body restoration, and collision repair alike. By embracing these eco-conscious approaches, professionals in the automotive industry can contribute to a greener future while meeting the highest standards of repair efficiency and effectiveness.

Case Studies: Eco-Friendly Dog Leg Repair in Action

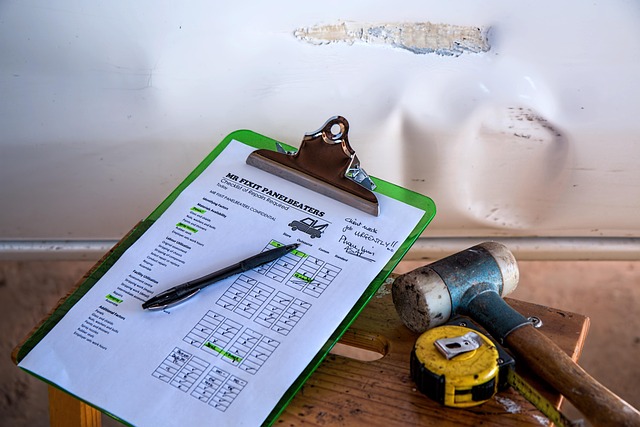

In recent years, there has been a growing trend among forward-thinking auto repair shops and car body repair centers to adopt eco-friendly practices in their dog leg repair processes. These case studies highlight successful implementations where environmental considerations have not only minimized waste but also enhanced the structural integrity of vehicles.

One notable example involves an auto collision center that integrated biodegradable materials into their dog leg repair kits, reducing the carbon footprint associated with traditional metal components. Additionally, they implemented a closed-loop recycling system for metal scrap, ensuring minimal waste during the car body repair process. This innovative approach has not only garnered industry recognition but also set a new standard for sustainable dog leg repairs in the region.

In conclusion, environmental considerations play a pivotal role in shaping the future of dog leg repair. By adopting sustainable materials and eco-conscious practices, we can significantly reduce the ecological footprint associated with this construction technique. The case studies presented demonstrate that eco-friendly approaches are not only feasible but also aesthetically pleasing and durable. As awareness grows among professionals and homeowners alike, the demand for environmentally responsible dog leg repair is poised to rise, fostering a greener built environment for generations to come.