Dog leg damage in commercial vehicles requires prompt repair by skilled technicians to prevent severe collision risks. Effective repairs demand specialized tools, inventory of replacement parts, and meticulous attention to detail for structural integrity restoration.

“Maintain the integrity of your fleet with our comprehensive guide to dog leg repair, a crucial aspect of commercial vehicle upkeep. Dog legs, vital components in suspension systems, often suffer damage due to rugged terrain and heavy loads. This article equips managers and mechanics with essential knowledge and practical tips. From identifying common issues to mastering a step-by-step restoration process, you’ll discover the tools, materials, and techniques needed for efficient dog leg repair, ensuring your vehicles remain reliable and safe on the road.”

- Understanding Common Dog Leg Damage in Vehicles

- Essential Tools and Materials for Repair

- Step-by-Step Guide to Effective Dog Leg Restoration

Understanding Common Dog Leg Damage in Vehicles

Dog legs, or suspension components, are integral to a vehicle’s overall performance and stability. In fleet and commercial vehicles, which often face more rigorous driving conditions and heavier loads, dog leg damage is a common concern. This type of damage can occur due to various factors such as uneven road surfaces, sharp turns, or sudden stops, leading to stress and strain on these critical parts over time.

Regular inspection and proactive maintenance are essential for identifying potential issues early on. Signs of dog leg damage may include unusual vibrations, noise during driving, or visible wear and tear. Promptly addressing these concerns through specialized automotive repair services is crucial in preventing more severe collision damage repair needs. Skilled technicians can perform expert dog leg repairs, ensuring the safety and smoothness of commercial vehicle operations.

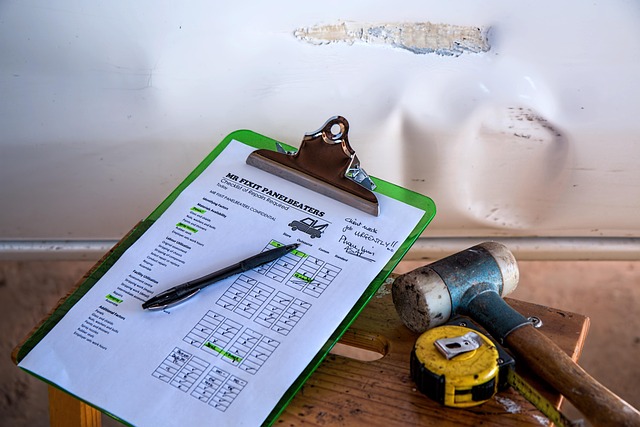

Essential Tools and Materials for Repair

When it comes to performing a dog leg repair on fleet or commercial vehicles, having the right tools and materials is paramount for a successful and safe fix. This includes robust and precise cutting tools like saws and shears, along with a variety of fasteners such as bolts, nuts, and washers in different sizes suitable for the vehicle’s make and model.

Additionally, a well-stocked inventory of replacement parts specific to dog leg repairs is essential. These may include new hinges, brackets, and other structural components. For vehicles that have suffered a collision, consider also having access to auto glass repair kits and other related materials, as these are often necessary to restore the vehicle’s integrity and safety features following an accident.

Step-by-Step Guide to Effective Dog Leg Restoration

Restoring a dog leg on a fleet or commercial vehicle is a crucial task that requires precision and expertise. Here’s a step-by-step guide to ensure effective dog leg repair for Mercedes Benz collision repair or any similar vehicle dent repair needs. First, inspect the damaged area thoroughly to understand the extent of the damage. This includes checking for cracks, dents, or any misalignment in the metal panel.

Next, gather all necessary tools and equipment, such as a hammer, pry bar, welding machine, and body putty. Begin by carefully removing any loose debris and then use the pry bar to gently pull back the damaged panel. Once exposed, assess the internal structure and make any necessary cuts to remove severely damaged sections. After cleaning and preparing the area, apply body putty to fill in any gaps or imperfections, smoothing it out for a seamless finish. Allow the putty to dry completely before moving on to the next step, which involves using a welder to precisely join the repaired panel with the surrounding vehicle body, ensuring proper alignment and structural integrity in vehicle body repair.

Dog leg repair is a crucial aspect of fleet and commercial vehicle maintenance, addressing a common yet detrimental issue. By understanding the damage, having the right tools, and following a systematic approach, technicians can effectively restore dog legs, ensuring the safety and longevity of vehicles. This process not only saves costs but also contributes to a smoother, more efficient transportation network. Remember, prompt action on dog leg repairs is key to preventing further damage and keeping your fleet in top condition.